Products

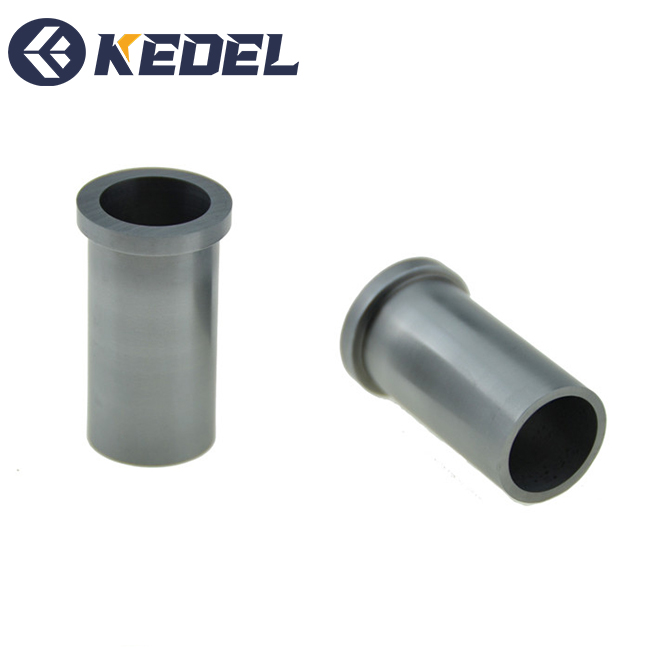

Anti Corrosion Tungsten Carbide Solid YG1C Threaded Drill Bushings

Product Introduction

Tungsten carbide bushing set up by virgin tungsten carbide material. It’s shows high hardness and bending strength. That has superior performance on resisting abrasion and corrosion, which is widely used in many industries

For its widely usage. Tungsten carbide bushing are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance. These are highly appreciated by the clients at domistic market and aboard.

In addition, differ from the various of application environment. There are several types of Tungsten carbide bushing. Most of the specifications are all customized. Kedel Tool has backed by rich industry knowledge and production experience of various Tungsten carbide bushing. This can produce various of Tungsten carbide bushing based on specific design.

Product Features

1. Use 100% tungsten carbide raw material

2. Stable chemical properties

3. Excellent performance and good wear / corrosion resistance

4. HIP sintering, good compactness

5. Blanks, high machining accuracy / precision

6. OEM customized sizes available

7. Factory’s offer

8. Strict products quality inspection

Detail drawing

Material table

| Grade | ISO | Specification | Application of tungsten carbide | ||

| Density | TRS | Hardness | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, non-metal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Qualified for low speed rough machining, milling titanium alloy and refractory alloy, especially for cut-off tool and silk prick. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Qualified for molding the drills for heavy-duty rock drill: detachable bits used for deep hole drilling, rock drill trolley etc. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Qualified for hard rock drilling, steel bars with high compression ratios, pipe drawing, punching tools, core cabinet of powder metallurgy automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Qualified for making dies with low impact such as punching watch parts, battery shells, small screw caps etc. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Qualified for making mould of cold heading, cold stamping and cold pressing used for manufacturing standard parts, bearings etc. | |