Material Performance Table

Customization Service

We can accept customized services. We can make OEM according to your drawings and ODM according to your use needs.

The fastest delivery period of customized products is seven days.

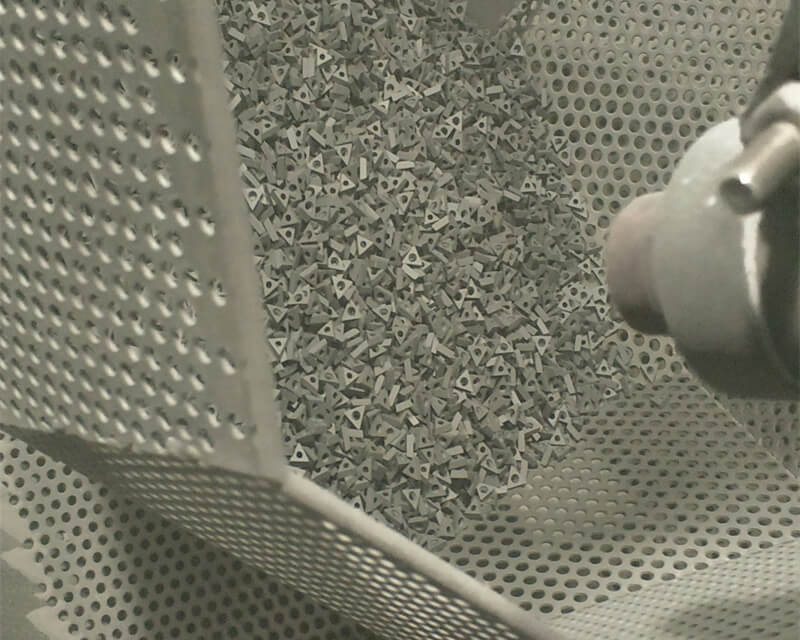

Production Process

3.Spray tower drying

4.Press molding

5.Low pressure sintering furnace sintering

6.Surface treatment-Sandblasting

7.Inspection

8.Finish grinding

9.Cleanign and packing

10.Factory re inspection

Return Policy

For the product quality problems confirmed by our company, we will timely reissue the new products that pass the inspection, and the transportation expenses shall be borne by our company. And return unqualified products in time

Logistics Service

We cooperate with four major international express companies, DHL, FedEx, UPS and TNT. Generally, the transportation time limit is between 7-10 days.

We also accept road, ail, airlines and sea transportation.

Quality Assurance

The quality guarantee period of our products is usually one year. If there are quality problems within the guarantee period, we can return and replace them, but we will not bear the problem of product damage caused by wrong use.

Quality Control

Raw material procurement---Blank production---Product finishing Maching---Coating processing

1. That is, WC, Co, Ta, Nb, Ti and other cemented carbide production materials are purchased into the factory for quality inspection.

2. Batching, ball milling, granulation, pressing, sintering, blank physical property test, and enter the next process after passing the test.

3. The blank passes through the processing processes such as outer circle, inner hole, end face, thread, forming grinding and edge treatment, and enters the next process after passing the inspection.

4. Coating strategic cooperation enterprises include Balchas, aenbond, Suzhou Dingli, etc. the coating will be warehoused after passing the inspection.