Products

High precision raw pure tungsten cemented carbide bar carbide polished rods

Product Introduction

Tungsten Carbide is often referred to as a Hard Metal due to it’s very high hardness in relation to other metals. Typically a Tungsten Carbide can have a hardness value of 1600 HV, whereas mild steel would be in the region of 160 HV a factor of 10 lower. Tungsten Carbide Rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel based alloy, titanium alloy and nonferrous metals. With several years’ development, with our good quality and competitive price, our products have been widely recognized by worldwide makers of cutting tools.

Advantages

1. ISO 9001:2015 Certification

2. Use 100% tungsten carbide raw material

3. Advanced technology , automatic pressing , HIP sintering

4. with over ten year experience

5. And precision grinding

6. the tolerance of polish and ground can be +0.005/-0.005mm

7. Full ability to accept OEM & ODM orders

8. Stringent quality control and quality consistency.

9. Strict inspection for quality of raw material and finished products

Appliction

Product Details

Material Introduction

| Grade Introduction to Carbide Rods | |||||||

| Grade | Co % | WC grain size | HRA | HV | Density (g/cm³) | Bending strength(MPa) | Fracture toughness(MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Fine | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

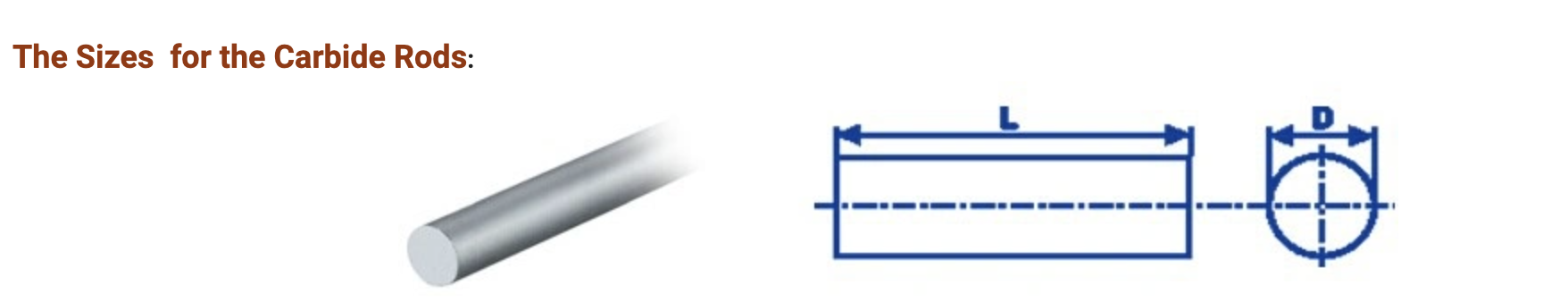

Common Referencesizes

| Solid Carbide Rods (Full length) | |||||

| Nominal Dia | D(mm) | D(mm) | Length | Remarks | |

| D (mm) | Un-ground | h6 | mm | ||

| 0.5 | 0.7 | 0.5 | 310-330 | ||

| 0.8 | 1 | 0.8 | 310-330 | ||

| 1 | 1.2 | 1 | 310-330 | ||

| 1.5 | 1.7 | 1.5 | 310-330 | ||

| 1/16" | 1.5875 | 1.8 | 1.5875 | 12" -13" | inch size |

| 2 | 2.2 | 2 | 310-330 | ||

| 2.35 | 2.55 | 2.35 | 310-330 | ||

| 3/32" | 2.38 | 2.6 | 2.38 | 12" -13" | inch size |

| 2.5 | 2.7 | 2.5 | 310-330 | ||

| 3 | 3.2 | 3 | 310-330 | ||

| 1/8" | 3.175 | 3.4 | 3.175 | 12" -13" | inchi size |

| 3.5 | 3.7 | 3.5 | 310-330 | ||

| 5/32 | 3.968 | 4.2 | 3.968 | 12" -13" | inchi size |

| 4 | 4.2 | 4 | 310-330 | ||

| 4.5 | 4.5 | 310-330 | |||

| 3/16" | 4.7625 | 5 | 4.762 | 12" -13" | inch size |

| 5 | 5.2 | 5 | 310-330 | ||

| 5.5 | 5.7 | 5.5 | 310-330 | ||

| 6 | 6.2 | 6 | 310-330 | ||

| 1/4" | 6.35 | 6.6 | 6.35 | 12" -13" | inch size |

| 6.5 | 6.7 | 6.5 | 310-330 | ||

| 7 | 7.2 | 7 | 310-330 | ||

| 7.5 | 7.7 | 7.5 | 310-330 | ||

| 5/16" | 7.937 | 8.2 | 7.937 | 12" -13" | inch size |

| 8 | 8.2 | 8 | 310-330 | ||

| 8.5 | 8.7 | 8.5 | 310-330 | ||

| 9 | 9.2 | 9 | 310-330 | ||

| 9.5 | 9.7 | 9.5 | 310-330 | ||

| 3/8" | 9.525 | 9.7 | 9.525 | 12" -13" | inch size |

| 10 | 10.2 | 10 | 310-330 | ||

| 10.5 | 10.7 | 10.5 | 310-330 | ||

| 11 | 11.2 | 11 | 310-330 | ||

| 7/16" | 11.11 | 11.3 | 11.11 | 12" -13" | inch size |

| 11.5 | 11.7 | 11.5 | 310-330 | ||

| 12 | 12.2 | 12 | 310-330 | ||

| 12.5 | 12.7 | 12.5 | 310-330 | ||

| 1/2" | 12.7 | 12.9 | 12.7 | 12" -13" | inch size |

| 13 | 13.2 | 13 | 310-330 | ||

| 13.5 | 13.7 | 13.5 | 310-330 | ||

| 14 | 14.2 | 14 | 310-330 | ||

| 9/16" | 14.288 | 14.5 | 14.288 | 12" -13" | inch size |

| 14.5 | 14.7 | 14.5 | 310-330 | ||

| 15 | 15.2 | 15 | 310-330 | ||

| 15.5 | 15.7 | 15.5 | 310-330 | ||

| 5/8" | 15.875 | 16.1 | 15.875 | 12" -13" | inch size |

| 16 | 16.2 | 16 | 310-330 | ||

| 16.5 | 16.7 | 16.5 | 310-330 | ||

| 17 | 17.2 | 17 | 310-330 | ||

| 17.5 | 17.7 | 17.5 | 310-330 | ||

| 18 | 18.2 | 18 | 310-330 | ||

| 18.5 | 18.7 | 18.5 | 310-330 | ||

| 19 | 19.2 | 19 | 310-330 | ||

| 3/4" | 19.05 | 19.3 | 19.05 | 12" -13" | inch size |

| 19.5 | 19.7 | 19.5 | 310-330 | ||

| 20 | 20.2 | 20 | 310-330 | ||

| 20.5 | 20.7 | 20.5 | 310-330 | ||

| 21 | 21.2 | 21 | 310-330 | ||

| 21.5 | 21.7 | 21.5 | 310-330 | ||

| 22 | 22.2 | 22 | 310-330 | ||

| 22.5 | 22.7 | 22.5 | 310-330 | ||

| 23 | 23.2 | 23 | 310-330 | ||

| 23.5 | 23.7 | 23.5 | 310-330 | ||

| 24 | 24.2 | 24 | 310-330 | ||

| 24.5 | 24.7 | 24.5 | 310-330 | ||

| 25 | 25.2 | 25 | 310-330 | ||

| 1" | 25.4 | 25.7 | 25.4 | 12" -13" | inch size |

| 26 | 26.3 | 26 | 310-330 | ||

| 27 | 27.2 | 27 | 310-330 | ||

| 28 | 28.2 | 28 | 310-331 | ||

| 29 | 29.2 | 29 | 310-333 | ||

| 30 | 30.2 | 30 | 310-334 | ||

| 31 | 31.2 | 31 | 310-335 | ||

| 1-1/4" | 31.75 | 32 | 31.75 | 12" -13" | inch size |

| 32 | 32.2 | 32 | 310-336 | ||

| 33 | 33.2 | 33 | 310-337 | ||

| 34 | 34.2 | 34 | 310-338 | ||

| 35 | 35.2 | 35 | 310-339 | ||

| 36 | 36.2 | 36 | 310-340 | ||

| 37 | 37.2 | 37 | 310-341 | ||

| 38 | 38.2 | 38 | 310-342 | ||

| 1-1/2" | 38.1 | 38.4 | 38.1 | 12" -13" | inch size |

| 39 | 39.2 | 39 | 310-343 | ||

| 40 | 40.2 | 40 | 310-344 | ||

| 42 | 42.2 | 42 | 310-344 | ||