Products

Corrosion Resistance Polished Tungsten Carbide Bushing Sleeve

Product Introduction

The cemented carbide axle sleeve will be used mainly for rotating support,aligning anti-thrust and seal of the axle of moter, centrifuge, protector and separator of the submerged electric pump in the adverse working conditions of high speed rotation, sand lash abrasion and gas corrossion in the oil field, such as slide bearing sleeve, motor axle sleeve, aligning bearing sleeve, anti-thrust bearing sleeve and seal axle sleeve.

Advantages

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

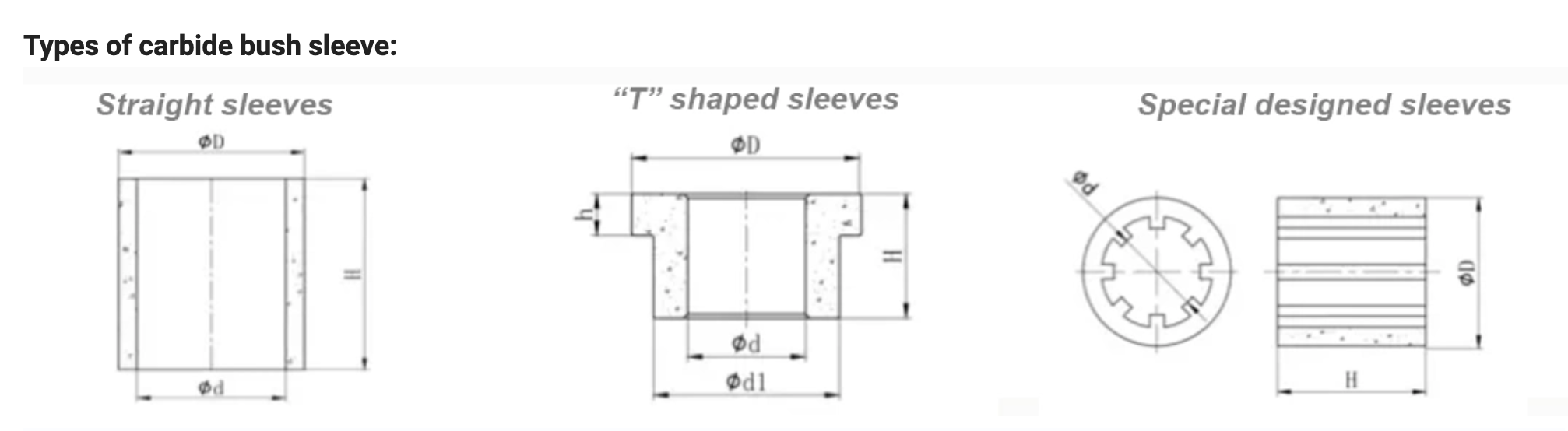

Casing type

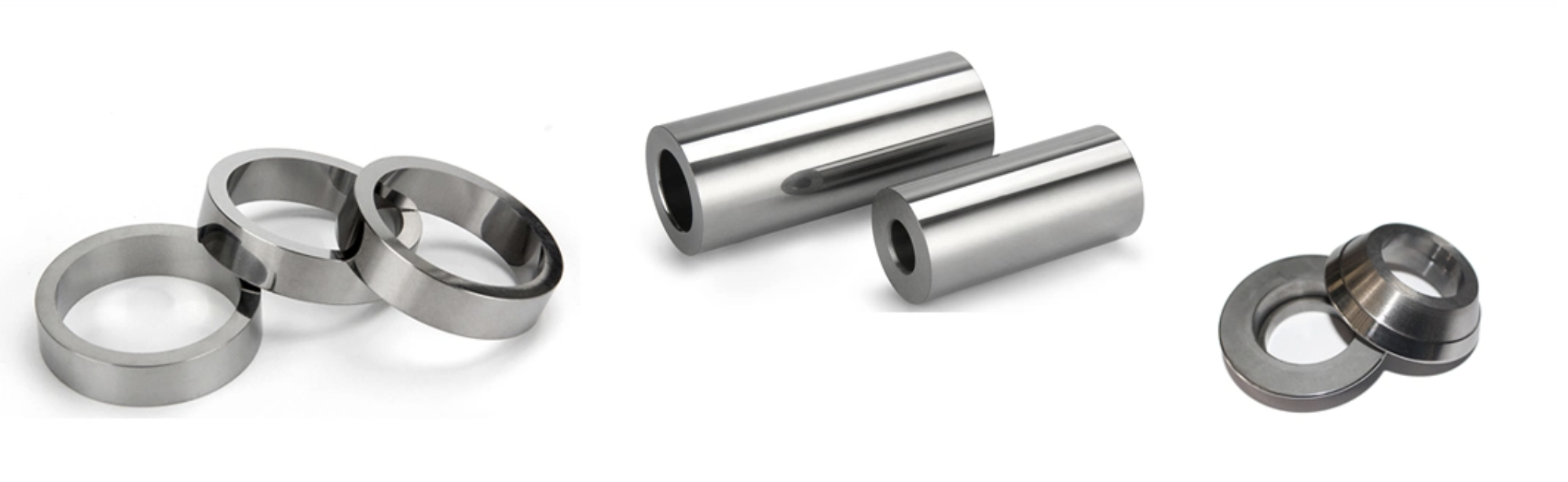

Casing picture

Material table

| Grade | ISO | Specification | Application of tungsten carbide | ||

| Density | TRS | Hardness | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, non-metal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Qualified for low speed rough machining, milling titanium alloy and refractory alloy, especially for cut-off tool and silk prick. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Qualified for molding the drills for heavy-duty rock drill: detachable bits used for deep hole drilling, rock drill trolley etc. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Qualified for hard rock drilling, steel bars with high compression ratios, pipe drawing, punching tools, core cabinet of powder metallurgy automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Qualified for making dies with low impact such as punching watch parts, battery shells, small screw caps etc. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Qualified for making mould of cold heading, cold stamping and cold pressing used for manufacturing standard parts, bearings etc. | |