Products

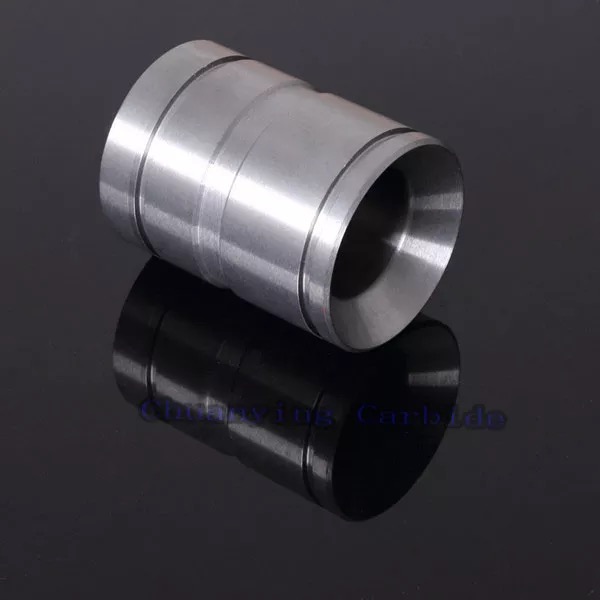

Cemented Tungsten Carbide Bushing Shaft Sleeve Bushing Bearing

Products Description

Cemented carbide polished bushigns bearings are the customized product of our company for customers. It has the properties of high wear resistance, high hardness and strong corrosion resistance. It can produce liners of different sizes and provide customers with unique and exclusive production and manufacturing capacity.

Kedel Carbide Components manufactures the highest-quality Tungsten Carbide, Ceramic and Tool Steel Wear Parts, M.W.D. Components and Specialty Components for corrosive and abrasive applications for the oil & natural gas industries.

We manufacture many parts such as flow control components, bushings, seats, gates and stems to carbide cutting bits, ported flow cages and thrust bearings.

Many Oil & Gas Companies rely on Kedel Carbide Components to manufacture quality, long-lasting tungsten carbide flow control components. Our reputation of manufacturing quality wear parts and flow control components stems from our experience in the industry, advanced tungsten carbide grades and commitment to our customers.

Our Features

1. Focus on the production of cemented carbide industry for more than 15 years;

2. The ingredients of various brands are complete, which can meet the performance requirements of failure;

3. Strong processing capacity, more than 50 CNC machine tools, more than 20 peripheral grinders and more than 20 universal processing grinders;

4. Customized production for customers, OEM and ODM;

5. Rich foreign customer service experience, serving customers in more than 50 countries around the world.

More Tungsten Carbide Bushings Bearing Bush

Material Performance Table

| Cobalt Binder Grades | ||||

| Grade | Binder (Wt%) | Density (g/cm3) | Hardness (HRA) | TRS (>=N/mm²) |

| YG6 | 6 | 14.8 | 90 | 1520 |

| YG6X | 6 | 14.9 | 91 | 1450 |

| YG6A | 6 | 14.9 | 92 | 1540 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| YG12 | 12 | 14.2 | 88 | 1810 |

| YG15 | 15 | 14 | 87 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |

| YG25 | 25 | 12.1 | 84 | 2550 |

| Nickel Binder Grades | ||||

| Grade | Binder (Wt%) | Density (g/cm3) | Hardness (HRA) | TRS (>=N/mm²) |

| YN6 | 6 | 14.7 | 89.5 | 1460 |

| YN6X | 6 | 14.8 | 90.5 | 1400 |

| YN6A | 6 | 14.8 | 91 | 1480 |

| YN8 | 8 | 14.6 | 88.5 | 1710 |