Products

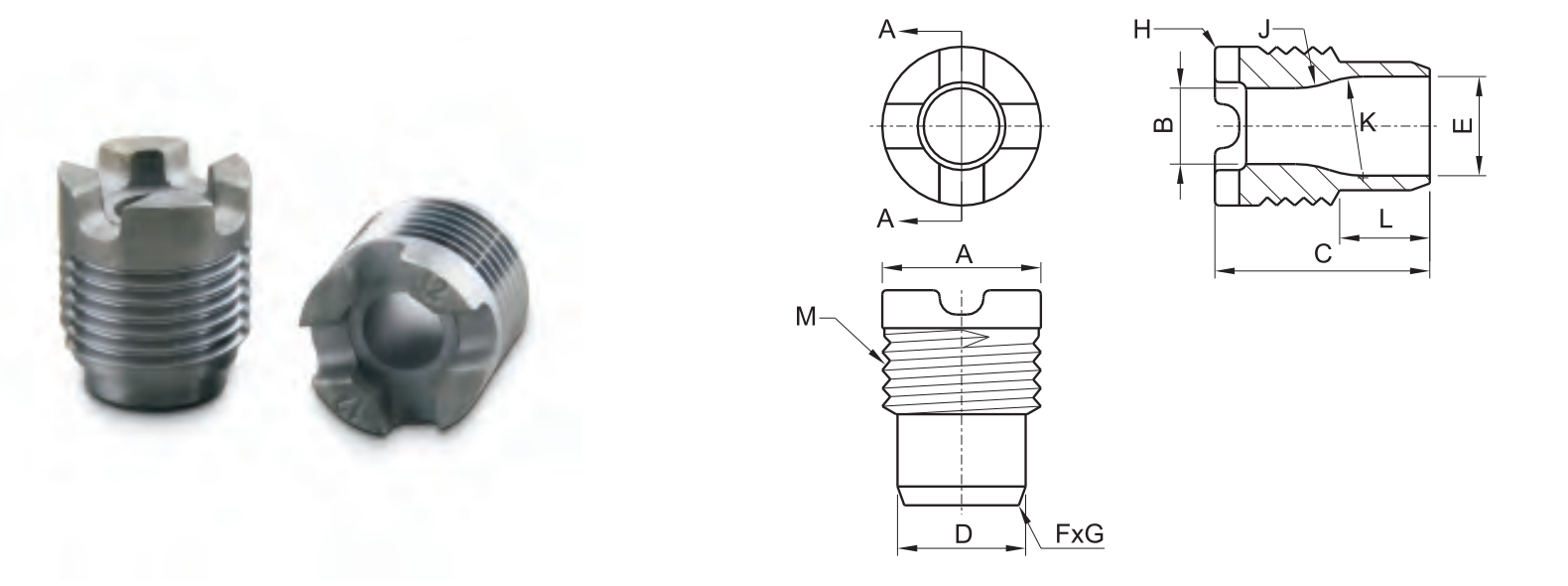

Tungsten Carbide Water Jet Nozzles

What makes tungsten carbide a great choice for nozzles?

• Super coarse grain hard alloy virgin raw material , 100% alloy by pressing and sintering , so that the hardness and toughness of the drill bit are increased by 30% simultaneously .

• Unique design, Drilling and digging speed raise 20%, life span extend 30%

• Dimensional stability in environments with high temperature and pressure conditions

• A fine finish which makes them easy to clean

• Great wear resistance, abrasion resistance

• Cost effective owing to long life span and negligible maintenance needs.

AdvantageMost Significant Factor

(1) under certain conditions, such as nozzle diameter, injection Angle and spray distance, the higher the jet pressure is, the better the rock-breaking effect will be;

(2) under the condition that nozzle diameter, injection Angle and nozzle moving speed are constant, the optimal spray distance increases with the increase of pressure, reaching 32.5 times of nozzle diameter at 200MPa;

(3) the essence of the nozzle moving speed is to reflect the action time of jet erosion rock. When it is less than 2.9mm/s, it has little impact on the erosion effect of rock.

(4) when the pressure is lower than 150MPa, the jet pressure increases and the rock-breaking volume per unit power increases rapidly; however, when the pressure increases further, the rock-breaking volume per unit power decreases slightly, and the rock-breaking efficiency is the highest at 150MPa.

(5) ultra-high pressure nozzle moves in forward mode, with the best rock-breaking effect and the best injection Angle of 12.50.

Details Of Products

Material Grade

|

Grade |

Co(%) |

Density(g/cm3 ) |

Hardness(HRA) |

TRS(NN/mm²) |

|

YG6 |

5.5-6.5 |

14.90 |

90.50 |

2500 |

|

YG8 |

7.5-8.5 |

14.75 |

90.00 |

3200 |

|

YG9 |

8.5-9.5 |

14.60 |

89.00 |

3200 |

|

YG9C |

8.5-9.5 |

14.60 |

88.00 |

3200 |

|

YG10 |

9.5-10.5 |

14.50 |

88.50 |

3200 |

|

YG11 |

10.5-11.5 |

14.35 |

89.00 |

3200 |

|

YG11C |

10.5-11.5 |

14.35 |

87.50 |

3000 |

|

YG13C |

12.7-13.4 |

14.20 |

87.00 |

3500 |

|

YG15 |

14.7-15.3 |

14.10 |

87.50 |

3200 |