Products

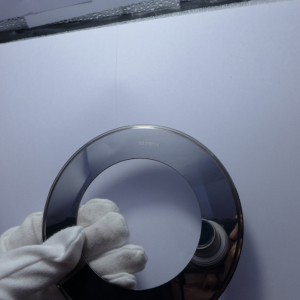

Top slitter blades & circular dished knives pneumatic slitting blades for lithium industry

Production Introduction

Kedel brand alloy blade has been developed since 2009. The product process is mature and the performance is good. It has cooperated with many domestic equipment manufacturers. The continuous slitting knife for lithium battery pole pieces produced by our company is made of cemented carbide powder pressed and sintered. It has the characteristics of high hardness, strong wear resistance and anti sticking knife. Specialized in solving various bad phenomena such as sticking knife, dust, burr, knife back print, wavy edge, color difference, etc. The full inspection blade is enlarged by 500 times without notch. During the cutting process of the positive and negative electrode pieces of the lithium battery blade, the collapse and burr caused by the poor quality of the cutting edge will cause the battery short circuit problem and form a serious safety hazard. Chengdu kedel tools has many years of experience in the production of cemented carbide industrial tools. All alloy billets are produced by itself. It has a deep understanding of the grinding process of alloy tools. Adhering to the spirit of "craftsman", strictly control the blade size tolerance. The unique edge precision machining technology and 100% automatic edge equipment full inspection process ensure the excellent performance of the lithium battery electrode slice slitter.

Product Features

1. Easy and fast cut,sharp cutting, non stick knife

2. Consistent sharpness and long service life due to 100% raw material.

3. Evenly distributed hardness and excellent wear resistance.

4. Stable performance and reduced machine downtime.

5. Competitive price.

6. Guaranteed global delivery.

Material

|

Grade |

Grain Size |

Density(g/cm³) |

HRA |

Fracturetoughness (kgf/mm²) |

TRS(MPa) |

|

KS26D |

sub-fine |

14.0-14.1 |

90.4-90.8 |

19-20 |

4000-4800 |

Main specifications and dimensions

|

Common Sizes |

||||

|

NO. |

Product Name |

Dimentions(mm) |

Edge angle |

Applicable cutting materials |

|

1 |

Slitting top knife |

Φ100xΦ65x0.7 |

26°、30°、35°、45° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ100xΦ65x2 |

26°、30°、35°、45°90° |

||

|

2 |

Slitting top knife |

Φ100xΦ65x1 |

30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ100xΦ65x3 |

90° |

||

|

3 |

Slitting top knife |

Φ110xΦ90x1 |

26°、30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ110xΦ75x3 |

90° |

||

|

4 |

Slitting top knife |

Φ110xΦ90x1 |

26°、30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ110xΦ90x3 |

90° |

||

|

5 |

Slitting top knife |

Φ130xΦ88x1 |

26°、30°、45°90° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ130xΦ70x3/5 |

90° |

||

|

6 |

Slitting top knife |

Φ130xΦ97x0.8/1 |

26°、30°、35°45° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ130xΦ95x4/5 |

26°、30°、35°、45°90° |

||

|

7 |

Slitting top knife |

Φ68xΦ46x0.75 |

30°、45°、60° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ68xΦ40x5 |

90° |

||

|

8 |

Slitting top knife |

Φ98xΦ66x0.7/0.8 |

30°、45°、60° |

Ceramic diaphragm |

|

Slitting bottom knife |

Φ80xΦ55x5/10 |

3°、5° |

||

|

NOTE: Customization available per customer drawing or actual sample |

||||

Applicable machinne

BYD, Xicun, Yinghe, Yakang, Haoneng, Qixing, Rongheng, Hongjin, Weihang, Dongli, Dongli, Qianlima, CIS, xingheli, Dali, etc

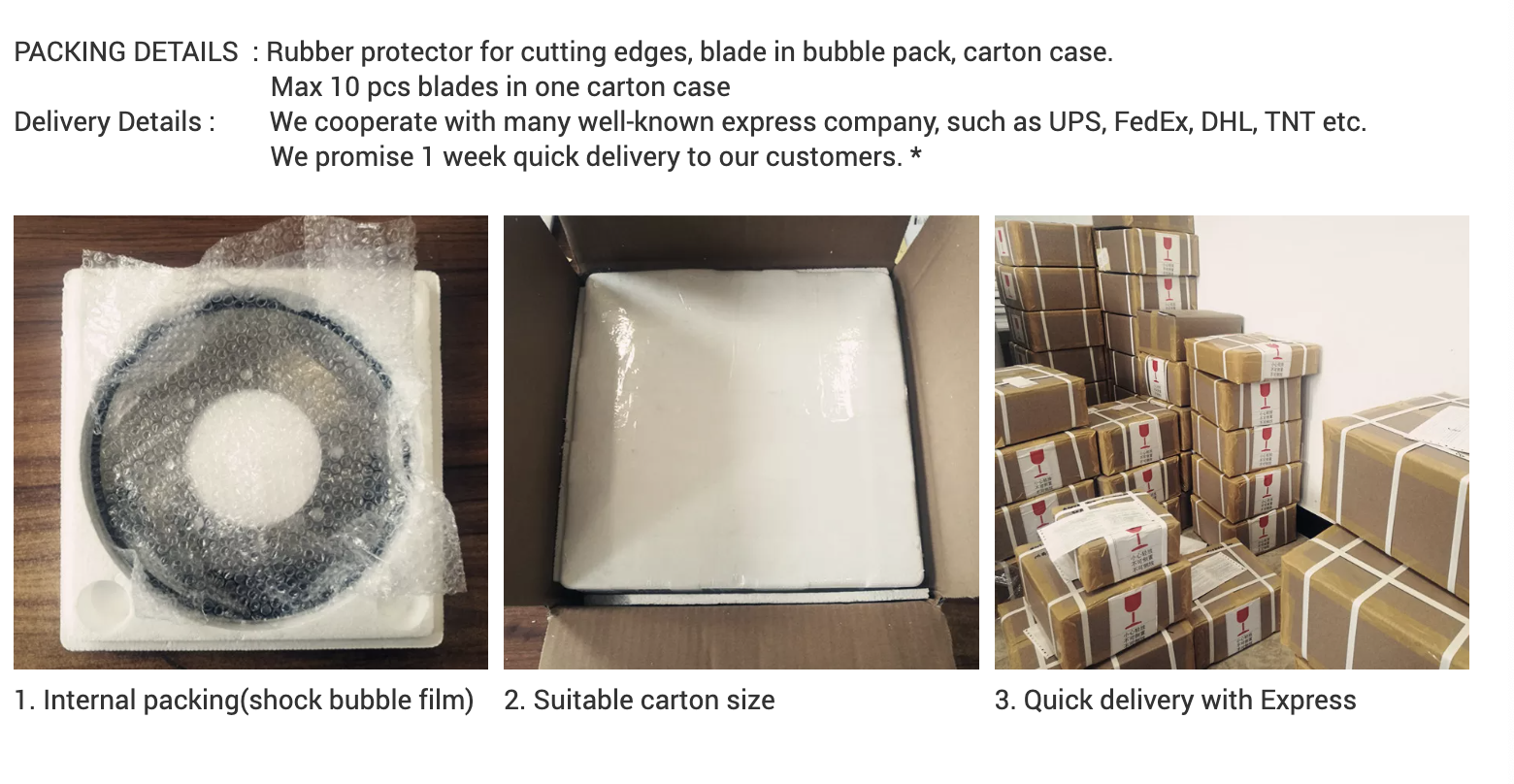

Packing and delivery

Application scenario