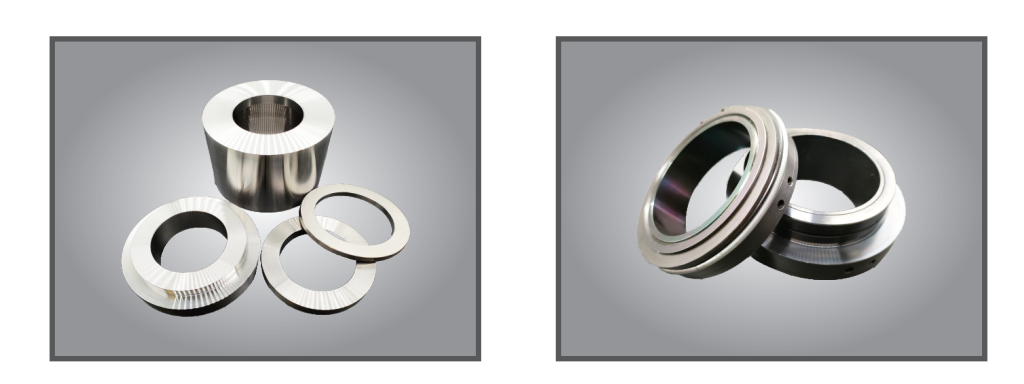

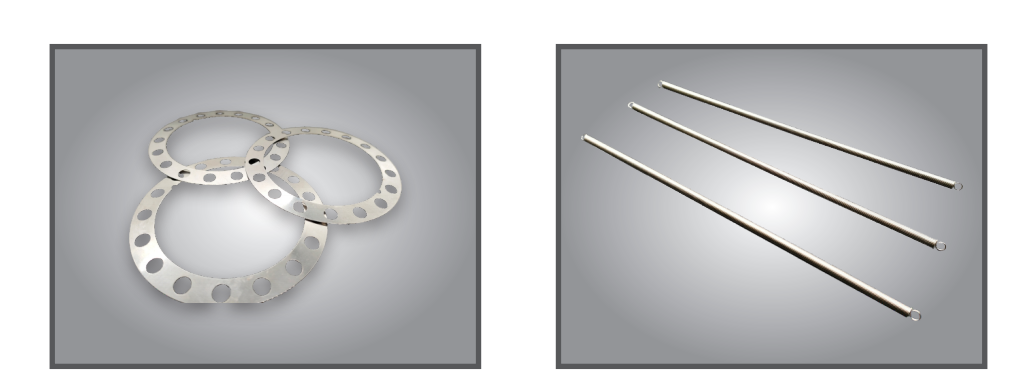

The lithium battery electrode cutting knife is produced from tungsten carbide and is widely used for cutting separators in new energy lithium batteries. It has good wear resistance and high machining accuracy. The outer circle accuracy of the tool is high, and the cutting edge is strictly enlarged and inspected. With fewer tool changes, long service life, and high cost-effectiveness, it is an ideal tool for battery industry users to reduce cutting costs and improve cutting quality.

Lithium ion batteries, as one of the new energy industries that have been a common focus of global development in recent years, are also an industry deeply cultivated and meticulously developed by Kedel Tools. The electrode cutting (cross cutting), diaphragm cutting, and non-ferrous metal cutting around the lithium-ion battery industry represent the highest level in the industrial cutting field. The technology in the lithium-ion battery industry is constantly innovating, and customer demands are constantly becoming more precise and diversified. In order to meet these needs, our company continues to invest in various precision equipment, improve our quality system management level, manufacture products that meet customer satisfaction, and make Kedel Tools a trustworthy partner for customers.

During the cutting process of positive and negative electrode plates in lithium-ion batteries, edge collapse and burrs caused by poor quality of the cutting blade can cause battery short circuits and pose serious safety hazards. Kedel Tools has over 18 years of experience in the production of hard alloy industrial cutting tools, producing all alloy billets themselves, and has a profound understanding of the grinding and processing of alloy cutting tools. Adhering to the spirit of "craftsmanship", we strictly control the dimensional tolerances of the blades. The unique precision machining technology and 100% automatic inspection process of the cutting edge ensure the excellent performance of the lithium-ion battery electrode cutting tool.

| Common Sizes | ||||

| NO. | Product Name | Dimentions(mm) | Edge angle | Applicable cutting materials |

| 1 | Slitting top knife | Φ100xΦ65x0.7 | 26°、30°、35°、45° | Lithium battery pole piece |

| Slitting bottom knife | Φ100xΦ65x2 | 26°、30°、35°、45°90° | ||

| 2 | Slitting top knife | Φ100xΦ65x1 | 30° | Lithium battery pole piece |

| Slitting bottom knife | Φ100xΦ65x3 | 90° | ||

| 3 | Slitting top knife | Φ110xΦ90x1 | 26°、30° | Lithium battery pole piece |

| Slitting bottom knife | Φ110xΦ75x3 | 90° | ||

| 4 | Slitting top knife | Φ110xΦ90x1 | 26°、30° | Lithium battery pole piece |

| Slitting bottom knife | Φ110xΦ90x3 | 90° | ||

| 5 | Slitting top knife | Φ130xΦ88x1 | 26°、30°、45°90° | Lithium battery pole piece |

| Slitting bottom knife | Φ130xΦ70x3/5 | 90° | ||

| 6 | Slitting top knife | Φ130xΦ97x0.8/1 | 26°、30°、35°45° | Lithium battery pole piece |

| Slitting bottom knife | Φ130xΦ95x4/5 | 26°、30°、35°、45°90° | ||

| 7 | Slitting top knife | Φ68xΦ46x0.75 | 30°、45°、60° | Lithium battery pole piece |

| Slitting bottom knife | Φ68xΦ40x5 | 90° | ||

| 8 | Slitting top knife | Φ98xΦ66x0.7/0.8 | 30°、45°、60° | Ceramic diaphragm |

| Slitting bottom knife | Φ80xΦ55x5/10 | 3°、5° | ||

| NOTE: Customization available per customer drawing or actual sample | ||||

| Grade | Grain Size | Density (g/cm³) | HRA | Fracturetoughness (kgf/mm²) | TRS (MPa) |

| KS26D | sub-fine | 14.0-14.1 | 90.4-90.8 | 19-20 | 4000-4800 |

Post time: May-28-2024